Behind every smartphone is a thousand tests

Shenzhen is home to Oppo’s biggest manufacturing facilities, although the brand is headquartered in neighboring Dongguan, just 90 kilometers to its north.

Shenzhen is perhaps best known to many as the mecca of electronic devices. The once-obscure city in China has grown to become the origin of almost every new gadget released in the market.

The city is the third largest city in China, next to Beijing and Shanghai, with an estimated population of around 18 million – a huge percentage of whom are migrants working in many large factories across the city.

Shenzhen is also home to Oppo’s biggest manufacturing facilities, although the brand is headquartered in neighboring Dongguan, just 90 kilometers to its north.

Our three-day visit to the city of Shenzhen was highlighted by a tour of Oppo’s office and manufacturing facility to learn how smartphones are made and tested before they are packed and shipped out to the rest of the world.

This is not the first time I joined a tour of this kind. About six years ago, I made a similar trip to one of the ODMs (original design manufacturers) in Dongguan flying from Manila to Hong Kong and taking a bus to cross the border of China through Guandong province.

However, this is the first time I witnessed how a smartphone is assembled and tested. The assembly lines are long and complicated, lined with machines flanked with dozens of workers that manually feed them with hundreds of parts. Every step is crucial but carefully and meticulously monitored, inspected and re-checked with machines and the naked eye. Each individual worker has a specific task that is repetitive, almost robotic in nature, but you can really see the efficiency and coordination in their movements.

This all starts in the SMT (surface-mount technology) Center where smartphone motherboards are produced by machines. Each of the 38 production lines can make close to 300 motherboards per hour for a total of about 7.5 million per month. Each motherboard goes through 18 quality inspection process – from micro-measurements to calibration and multiple inspections.

From the SMT Center, the motherboards are transferred to the assembly line where all the other smartphone parts are attached – the display module, camera module, chassis, battery, earpiece, antenna, etc. – by hand or with the use of specialized equipment.

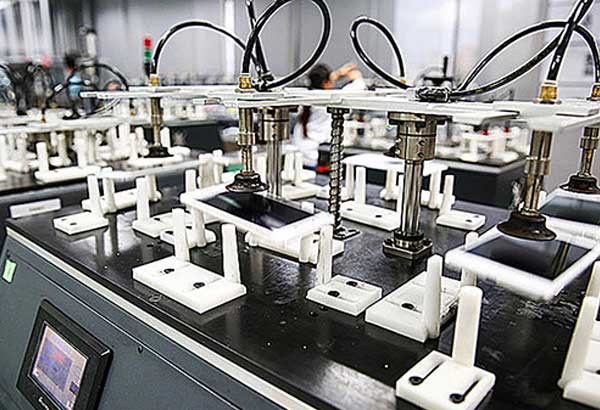

Each of the 26 assembly lines is configured into two sections – the assembly and testing. Once the smartphone is completely assembled, it goes through the testing phase. Workers test every part or function of the phone – power, volume, display, camera, signal and operating system. There are structural tests, electrical performance tests and environmental ageing tests done on a random set of phones, usually about 32 units for every 300 devices produced or just a little over 10 percent of the entire batch. The defect rate is controlled at under 0.02 percent and if it goes above that, the entire process is reviewed.

Some of the tests include a micro drop test of up to 42,000 times on all sides at a height of 7cm, tapping the side buttons (power and volume) with one kilogram of weight to up to 100,000 times while the fingerprint button is tapped one million times, a drop test from one meter and 1.5 meters, press test, tumble test, rain test, salt spray test, sweat test and environmental tests such as exposure to high temperatures. They test the device against exposure to common household liquids – soda, coffee, oil, lotion, gels, alcohol, and more.

In all, a typical Oppo smartphone will go thru over 150 kinds of tests and inspections. This ensures that the device is durable and can withstand various situations and environmental conditions.

After observing the entire process, one can definitely gain a better appreciation of the final product and what it has to go thru before it is packed, shipped and delivered to each and every Oppo customer.

- Latest